A key focus of my blog is Technology. Automation has been gradually implemented into our industries and there’s more to come. Not many people think about it in their day to day lives but it’s important for all of us to consider. The following contributed post is entitled, What Automation Can – And Can’t – Do For Us.

* * *

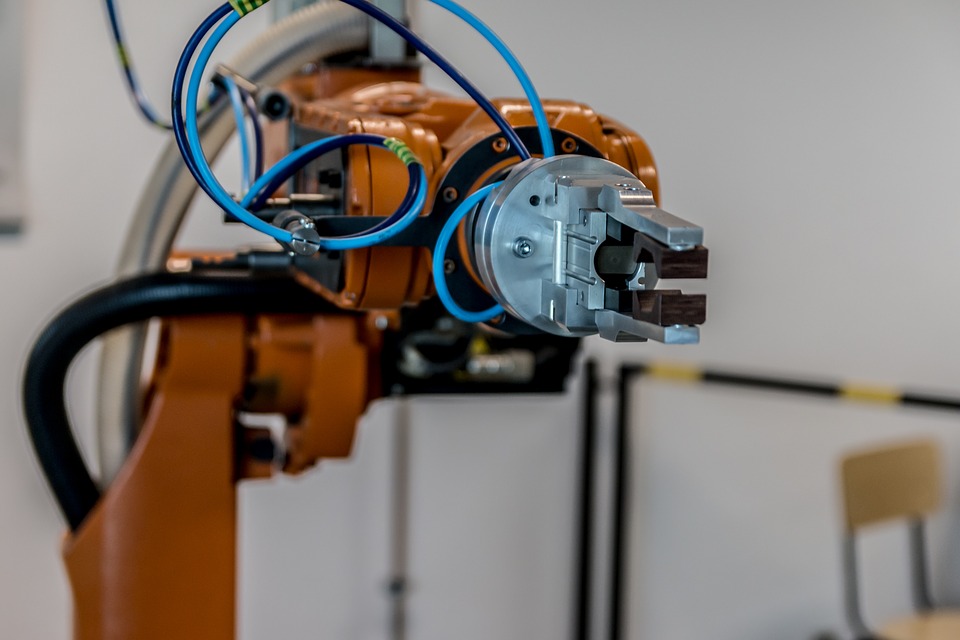

The very concept of automation is enough to spark a dozen conversations in which the questions range from a simple “good or bad?” to more complicated ones like “what does it mean for small business?”. There is no doubt that we are in a period of increasing technological involvement in our lives, both working and domestic. Opinions differ on what this says about where our future is going; it’s definitely a complicated issue.

Deciding how to feel about this rise in automation is tricky. On the one hand, it can depersonalize a workplace and lead to redundancies. On the other, automation can streamline working processes and keep things moving. There are arguments for and against, and below we’re going to look at a few of those in order to see if we’re ready for more automation in the working world.

Automated systems can work 24/7…

If you can successfully train a machine or code a program to do a job that is usually done by a person, then you have created a worker that never needs to eat or sleep. That means that you aren’t beholden to tight time frames that are dependent on shift workers whose performance will vary during the day as they get tired, hungry or distracted.

…but they can’t work off their own initiative

The flipside of these 24/7 workers that never eat or sleep is that they also can’t think. If a trained worker spots an anomaly in the work in front of them, they can alert someone to it. In many circumstances, they can fix the flaw themselves or devise a workaround. While much of the focus on automation looks at how it covers for human fallibility, that’s very much a two-way street and it’s why you need to have actual workers in the warehouse at all times.

Automated systems can replicate an instruction 100%…

Try, right now, to draw a perfectly straight line without a ruler. If you manage that, draw a perfect circle.

What you will notice is that you didn’t even get to step two, because a human being can’t physically do those things free-hand. There will always be a flaw. That’s what’s so exciting about smart manufacturing. It allows human vision to be made into something solid without the risk of flaws.

…but they can’t spot a logical flaw in an instruction

If you tell a machine to 3D-print a hairbrush that is 9” in length, it will do just that, and you’ll have a perfectly reasonable, nine-inch long hairbrush. If you get confused and tell the same machine to print a 9’ hairbrush, it’s going to try and print a nine-foot long hairbrush – and if it has the materials to do so, that’s what you’ll get. That’s what it’s been told to do, and the product will be flawless. Details like that, obvious to most experienced engineers, are why humans are a necessary part of the process.

Automation as a concept certainly has its upsides, and its incorporation into the world of work could solve a lot of problems. As long as this is done alongside a recognition of the essential part human ingenuity plays, it can end up being good for all of us.